Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

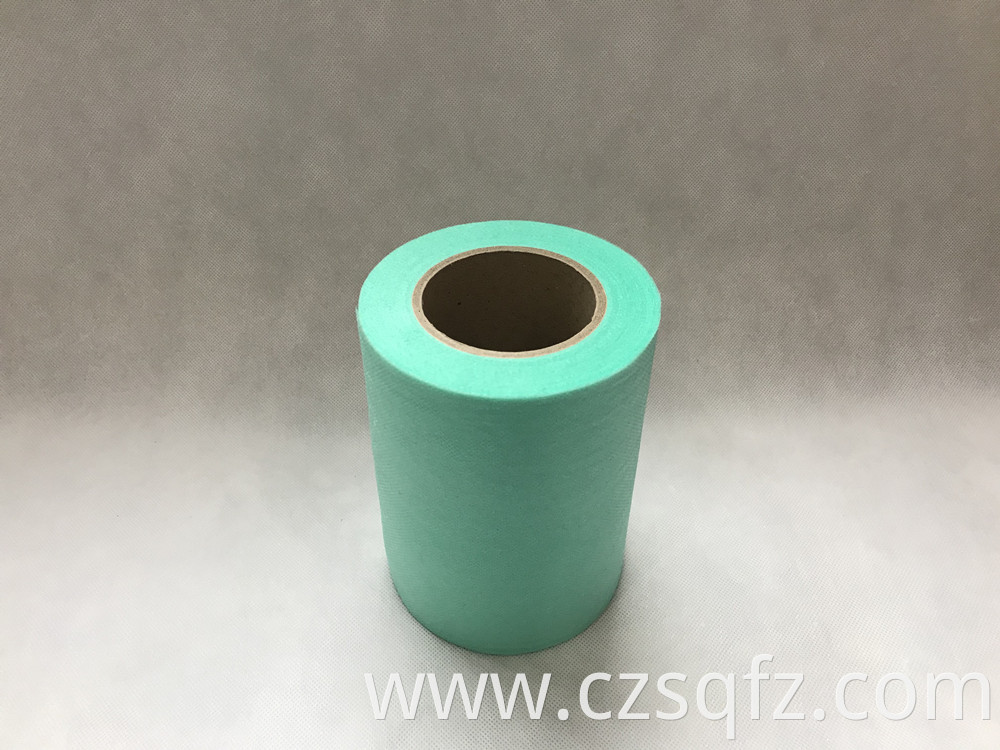

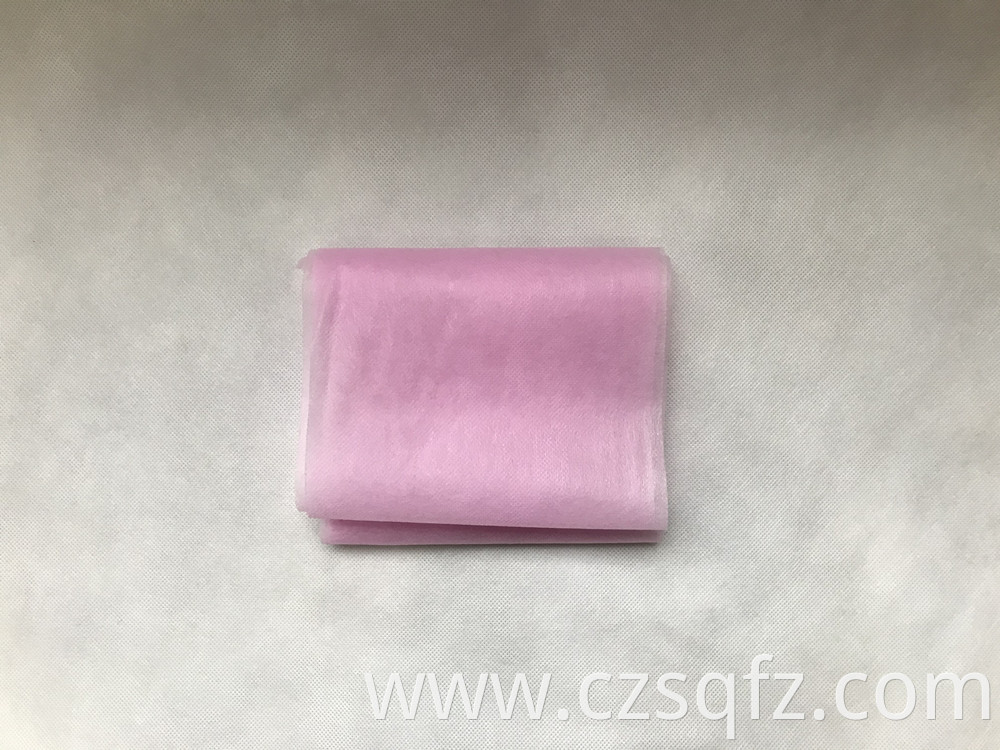

Craft: Nonwoven

Supply Type: Make-To-Order

Material: 100% Polypropylene

Non-woven Process: Spun-Bonded

Style: Dyed, Dot

Characteristic: Shrink-Resistant, Dimensional, Stain Resistant, Stain Repellent, Quick-Dry

Use: Home Textile, Garment, Car, Shoes, Bedding, Mattress, Luggage, Bags,Purses &Amp; Totes, Coat And Jacket, Outdoor, Pillows

Place Of Origin: China

Packaging: 2-layer plastic bag

Productivity: 20

Transportation: Ocean,Air

Supply Ability: 20 tons/day

Port: In Shanghai Port,Ningbo Port

Payment Type: L/C,T/T

Incoterm: FOB

Product Categories : Mask PP Non-woven Fabric > 100%PP25GSM Blue And White Mask Cloth

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.